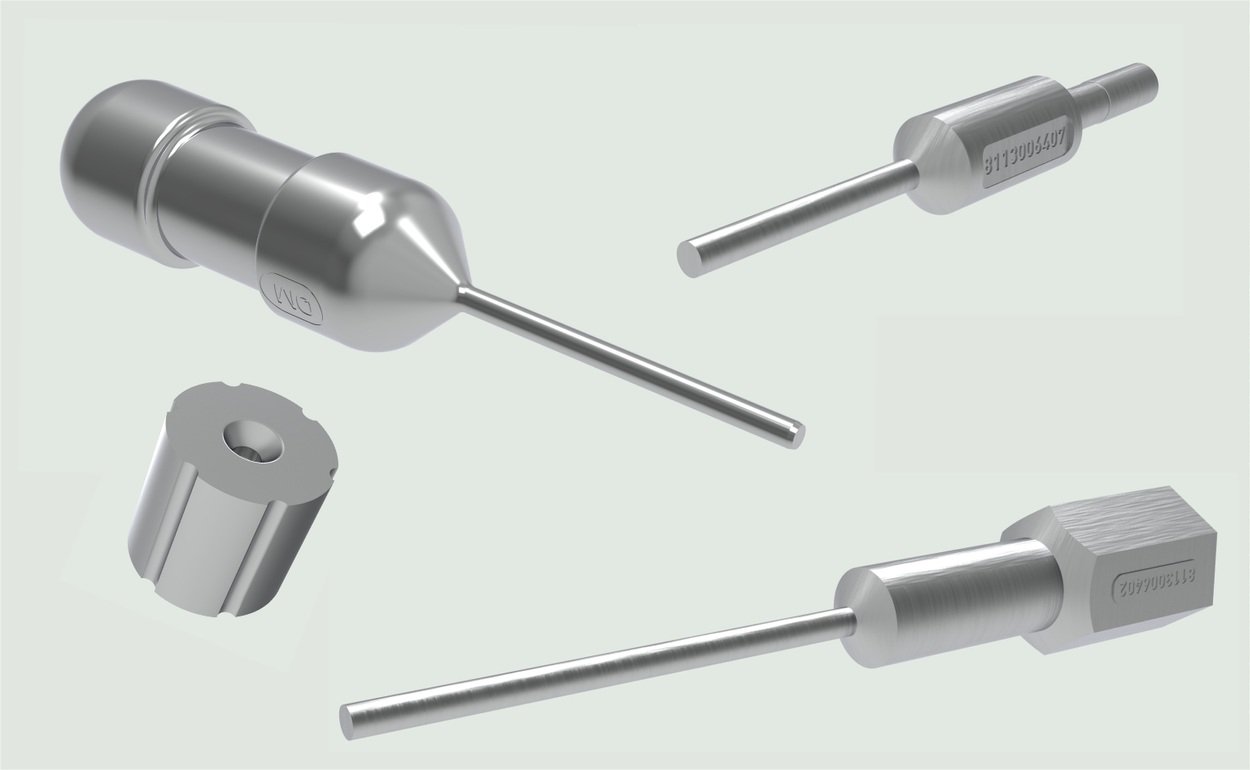

VAX-ID

Manufacturing of a vaccination tool.

Client

Novosanis x IDEVAX

Industry

Medical parts & devices

Duration

3 months

“Can you manufacture our vaccination device for our start-up?”

Koen Beyers – CTO & Founder, Novosanis

The start-up VAX-ID developed a hardware to ensure that everyone can administer a vaccine correctly on the epidermis. Fosfor managed the production within the predefined ISO standards, production qualifications and certifications.

— Objectives

AFFORDABLE INNOVATION

Since IDEVAX was still a start-up, the objective was to keep production costs minimal while maintaining high-quality standards.

PRECISION IN VACCINATION

IDEVAX offers a revolutionary injection system designed for precise vaccine delivery, ensuring accessibility and accuracy for all users.

— Some key features

MEDICAL DEVICE PRODUCTION

Our involvement extended beyond pure production; it included translating provided drawings into a validated process and mould. Compliance with medical device standards (ISO13485), IQ OQ PQ qualification for production, and CE certification were integral components of our engineering efforts.

Fosfor, in partnership with Novosanis, has not only realized an affordable and efficient hardware solution but has also contributed to the advancement of accessible and precise vaccine administration. As we navigate the complex intersection of engineering and medical standards, VAX-ID exemplifies our commitment to impactful solutions that shape the future of healthcare.

You have a groundbreaking idea to transform healthcare?

Talk with us!

Our team is happy to pingpong freely about the first possibilities.