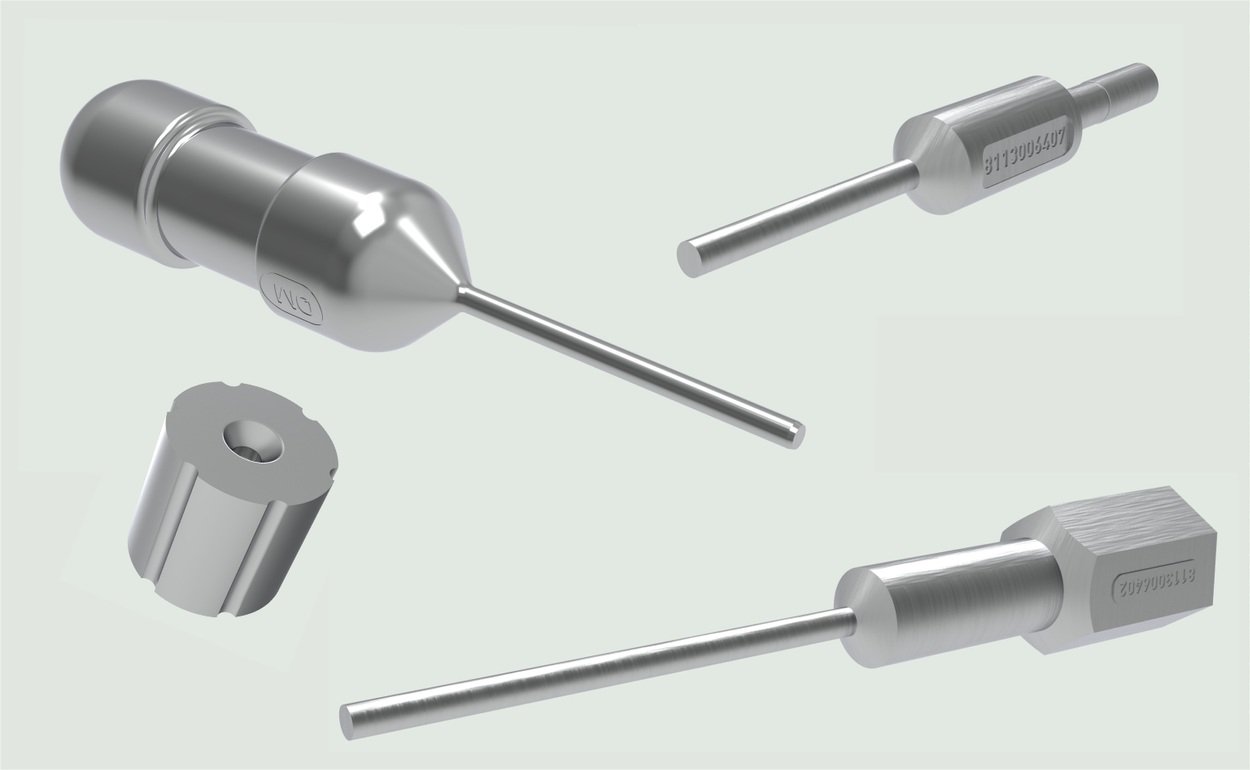

Titanium parts

Packaging line optimization

Client

Pfizer

Industry

Medical parts & devices

“Can Fosfor optimize our packaging line by finding an alternative for the deteriorating stainless-steel parts.”

Pfizer

Pfizer presented us with a challenge: to replace worn-out stainless-steel elements prone to sticking. Our team looked for alternatives and developed titanium parts, offering a robust substitute for the stainless-steel components.

— Objectives

PACKAGING LINE ENHANCEMENT

Pfizer sought our expertise to address a persistent challenge in their packaging lines. The objective was clear - replace stainless steel components, prone to wear and adhesion issues over time.

— Some key features

WEIGHT REDUCTION

An integral goal was to achieve weight reduction in the automation system. By replacing stainless steel with titanium (a third of the weight), we aimed to optimize the performance and efficiency of Pfizer's filling lines.

CNC & EDM PRECISION

The project focused on enhancing the overall efficiency of Pfizer's filling lines through strategic replacement and optimization. This involved leveraging advanced production techniques such as CNC (Computer Numerical Control) and Electric Discharge Machine (EDM).

By introducing durable and lightweight titanium components, we not only addressed challenges but also contributed to the long-term efficiency and reliability of Pfizer's automation systems. This project exemplifies our commitment to innovative problem-solving and precision engineering, shaping the future of manufacturing for our clients.

Want to optimize your manufacturing process too?

Talk with us!

Our team is happy to pingpong freely about the first possibilities.