Kneading machine

From manual handling to a faster & more efficient machine.

Client

Pfizer

Industry

Medical parts & devices

Duration

1 year

“How can we disassemble vacuum-packed plungers more efficiently?”

Pfizer

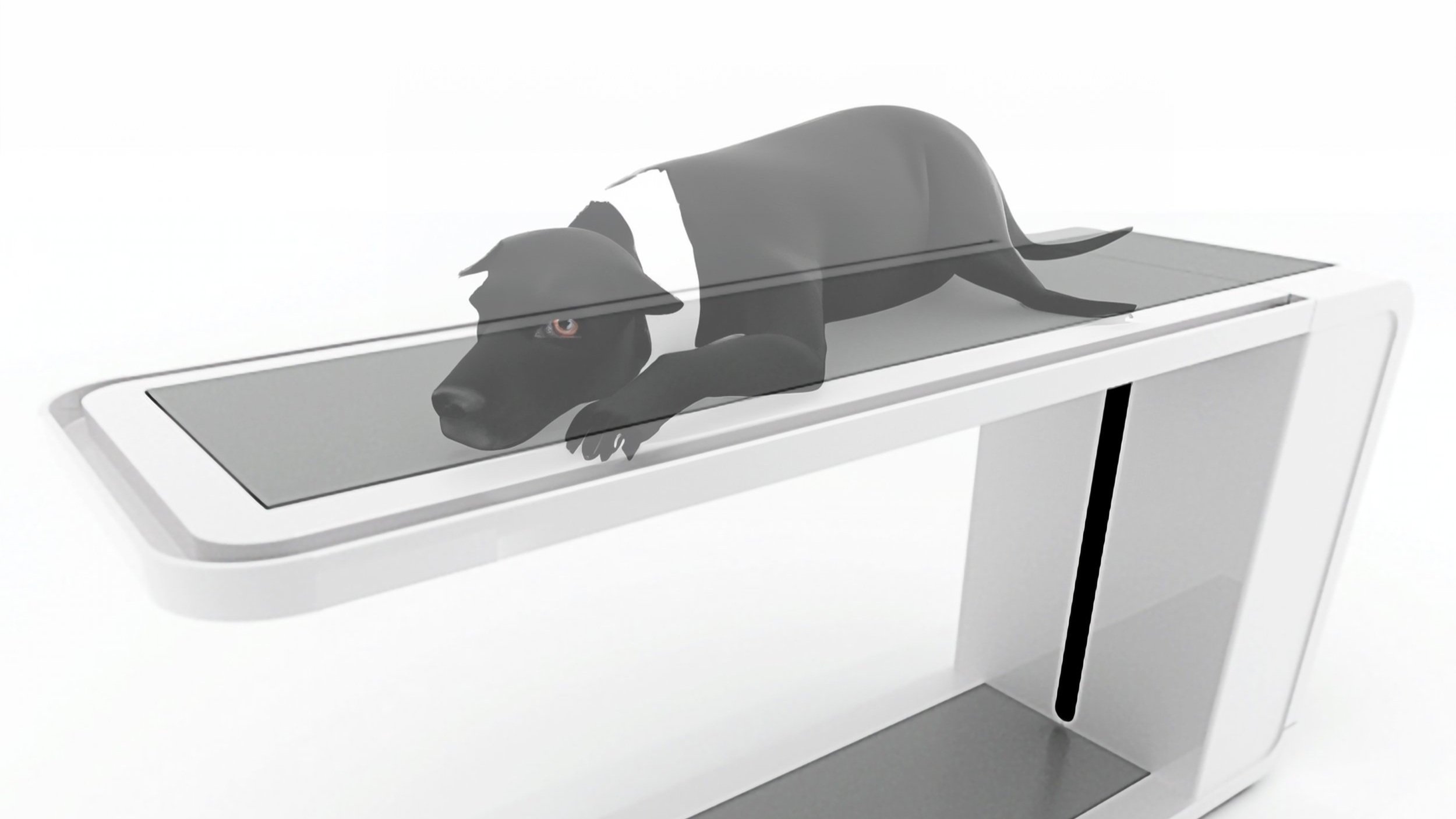

We proudly present the kneading machine project, a solution crafted to address Pfizer's challenge in disassembling plungers’ stoppers made from vacuum-packed elastomers. Faced with the need to disassemble these components efficiently for integration with other parts, Pfizer sought our expertise to automate the process.

— Objectives

AUTOMATED DISASSEMBLY

The primary objective was to devise a solution for the efficient disassembly of plunger’s stoppers made from vacuum-packed elastomers. The manual process was not only time-consuming but also prone to variations, prompting the need for a consistent and automated approach.

— Some key features

STREAMLINED DISASSEMBLY PROCESS

Our goal was to transition from manual labour to a machine-driven process that not only accelerated the workflow but also ensured uniformity in the disassembly, providing a foundation for improved system efficiency.

CONCEPT TO EXECUTION

Fosfor took the challenge head-on, moving from conceptualization to the implementation of the kneading machine. This innovative solution streamlined the previously manual and time-intensive task of disassembling elastomer-packed plungers’ stoppers.

Witness the evolution from manual intricacies to a seamless and consistent machine-driven solution, epitomizing the fusion of creativity and engineering excellence in the world of design innovation.

Want to streamline your healthcare manufacturing too?

Talk with us!

Our team is happy to pingpong freely about the first possibilities.